No products in the cart.

Manufacturer of Tank Top Services

We are proud to be a leader in the sportswear manufacturing industry, based in China. With over 15 years of experience, we provide high-performance tank tops that are crafted with precision, style, and functionality. Our commitment to quality and innovation ensures that every piece we produce is engineered to meet the highest standards. Whether you’re an established brand or a new player in the fitness and sportswear market, our OEM and ODM services offer the perfect solution to elevate your product line.

Customizable Fit & Design

Our tank tops can be fully customized with your logo, brand colors, and specific designs, creating a unique, recognizable tank top collection for you. Whether you’re looking for a relaxed fit for casual wear or a tighter, performance-oriented fit, we offer a range of cuts and styles to meet various body types and preferences. We use state-of-the-art dyeing techniques to ensure rich, vibrant colors that don’t fade. From bold neons to understated earth tones, our range of color options guarantees there’s something for every brand.

Cooperation Processing

Cooperating with us, your custom tank tops go through a smooth and professional manufacturing process designed to ensure quality, efficiency, and precision.

Fabric Preparation

Fabric selection: Use polyester blended fabrics that are sweat-absorbent, quick-drying and elastic to meet the comfort and durability during exercise.

Pre-shrinkage treatment: The fabric is treated with high-temperature steam in an automated pre-shrinkage machine to control the shrinkage rate of the subsequent finished product within 2% to ensure dimensional stability.

Digital Printing Process

Printing equipment: The factory has introduced a full set of imported wide-format digital printers, which can achieve CMYK and spot color printing with a high precision of up to 1,440 dpi.

Ink and sizing: Environmentally friendly disperse dye ink is used, and the sizing agent is applied to the fabric surface by spraying or padding to improve color penetration fastness.

Printing process: The fabric is automatically cut according to the design draft and accurately fed on the printing table, layered and superimposed color by color, and the color concentration and position deviation are monitored in real time to ensure accurate restoration of the pattern.

Color fixation and shaping: After printing, the fabric enters the shaping oven and is baked at 200℃ for 8-10 minutes to disperse and fix the dye in the fiber structure, which not only ensures color fastness but also prevents moisture reappearance.

Burnout Process

The burnout process is also called electrochemical corrosion. It uses special additives and templates to partially remove fibers on the surface of the fabric to form a hollow or relief effect.

Plate making and typesetting: First, a pattern template is etched on a corrosion-resistant metal plate, and then the template and the fabric are aligned by a high-precision typesetting machine.

Corrosion treatment: After power is turned on, the electrolyte impregnates the fabric along the template pattern. After a few seconds to tens of seconds of reaction, the fibers in the pattern area are corroded and dissolved to form a three-dimensional texture.

Neutralization and cleaning: Immediately after completion, use a weak alkaline solution to neutralize the residual acidity, followed by multiple rinses with clean water to ensure that there is no corrosive agent residue on the fabric.

Cutting & Sewing

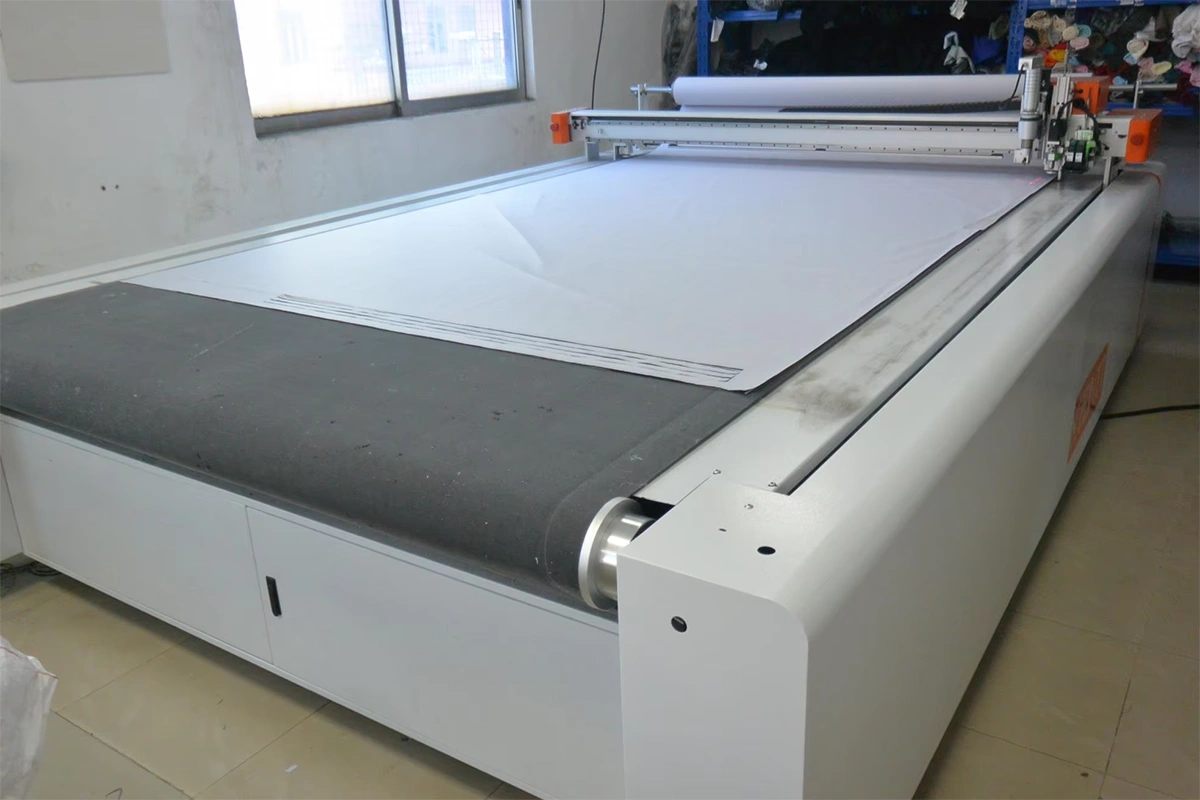

Automated cutting: After the printed and burned fabrics are rolled up, they are sent to the computer cutting machine and punched at high speed according to the digital pattern, with precise edges and a loss rate of less than 3%.

Sewing process:

- Professional sewing masters work in sections according to the assembly line

- Shoulder strap sewing: Strengthen the stitches and shoulder the weight;

- Side seams and hems: Use double needle hemming technology to prevent cracking during stretching;

- Neckline and armhole striping: Sewing rib strips according to ergonomic curves to increase elasticity and fit.

Sewing quality inspection: Professional quality inspectors use magnifying glasses and measuring calipers to spot check the stitching strength, stitch density and dimensional accuracy, and the qualified rate reaches 99.5%.

Finishing & Quality Inspection

Ironing and shaping: The finished vest is ironed and flattened by a high-pressure steam ironing machine to improve the feel and smoothness of the appearance.

Re-testing: The last color fastness, shrinkage and friction resistance test ensures that the product will not fade or deform even after multiple washings.

Packaging & Delivery

Folding and packaging: Individually packaged in OPP bags according to international standards, and anti-counterfeiting labels are affixed to the seal to demonstrate the reliability of brand traceability.

Warehousing and delivery: The product batches and inventory locations are entered into the warehouse management system (WMS), and the warehousing and delivery status is monitored in real time to ensure fast and accurate delivery to the global market.